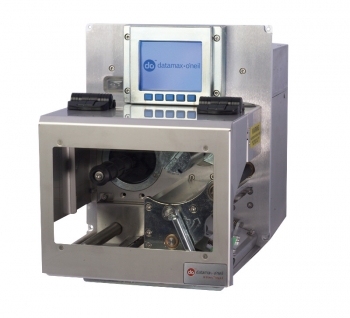

A – Class, Mark II Print Engine

When the demands of your high performance print and apply application require more features than existing print engines offer, it’s time to move up to the A-Class™ Mark II. The A-Class Mark II family of advanced print engines is designed for high-demand multi-shift applications requiring fast throughput and proven reliability. It includes a number of innovative design features such as stainless steel hardware components, a modular design for enhanced serviceability, coated side in/coated side out thermal transfer ribbon assembly, a full graphics display, intuitive menu navigation, and an optional remote display.

Designed for print and apply applicator integration, the A-Class Mark II utilizes the industry recognized Datamax-O’Neil firmware architecture with maximum connectivity options for industry standard communications interfaces. The A-Class Mark II with RFID option allows users to encode smart labels at the point of print, where most experts agree that encoding should take place to avoid any chance of mismatch between printed and encoded information. The RFID option currently accommodates EPCglobal Class 1/Gen 2 tags with either 64 or 96 bits of memory.

The A-Class Mark II is available in either 4” or 6” widths and is the only print engine to offer 203, 300, 400 and 600 dpi resolution in either right-hand or left-hand models.

Increased productivity – The A-Class increases productivity by providing fast throughput and proven reliability. The new design also allows for quick and easy replacement of the platen roller and printhead, cutting back on downtime and improving efficiency.

Integrates easily into existing solutions – The A-Class supports industry mounting standards for seamless integration into your system.

PL-Z (Zebra) and PL-I (Intermec) printer language emulation allows you to seamlessly integrate the A-Class into existing solutions without changing label formats.

Applications:

[one_third last=”no”]

Manufacturing

• Product Identification

• Shipping Labels

• Pallet Tracking Distribution

• Warehouse Logistics

• Cross Docking

• Shipping Labels

Food & Beverage

• Compliance

• Shipping Labels

• Product Identification[/one_third]

[one_third last=”yes”]

Pharmaceutical

• Compliance

• Product Identification

• Track & Trace

Health & Beauty

• Product Identification

• Shipping

• Track & Trace[/one_third]

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Datamax-Oneill – AClassMII_final_rev0505101Markoprint ZTV HP

The Markoprint ZTV HP is a Central Ink Supply (CIS) system stores up to 400ml of ink for Markoprint HP Class inkjet printing systems such as the Markoprint integra One, Markoprint X2JET / X4JET, and Markoprint integra Quadro.

The large ink tank prevents frequent cartridge replacements from lowering your Overall Equipment Effectiveness (OEE). It can hold up to four single HP cartridges repaying you rapidly thanks to reduced ink prices. For non-interrupted production, the system can be paired with our NonStopPrinting printhead. Using an interface directly on the cartridge, current ink filling levels are monitored in real time. When the levels in the bulk tank fall below a certain threshold, a valve to the bulk tank opens and automatically refills it.

View ProductMarkoprint Integra One

Labeling systems are not always easy to integrate into preexisting production lines. The Markoprint Integra One can be easily integrated into production processes thanks to its compact dimensions of 186 x 86 x 98 mm. The printing system has a display for data entry as well as system settings modification and verification. This information can also be viewed from mobile devices if the WLAN version is selected.

Inkjet printers should be properly protected if they are subjected to harsh manufacturing circumstances. In addition, the Markoprint integra One ip has an IP 65 protection rating. As a result, it’s ideal for use in the food industry.

View ProductX1Jet HP Premium MK2

The innovative Markoprint X1JET HP inkjet printer codes absorbent and semi-absorbent surfaces quickly, accurately and reliably. It is designed for a different range of applications in the food and beverage industry as well as the chemical and pharmaceutical industry. The controller and printer are combined in one single unit, making the system extremely compact.

View ProductGeset 111 Top Labelling System

The Geset 111 labelling system is used to label square products on the top side automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage on the labelling system. Care should be taken on accurate alignment of the products. It is essential that the products are forwarded separately to the applicator with a gap between each other.

When the barrier is reached, an application trigger is tripped. The label applicator applies a label on the product in Wipe On procedure. The label on the top side is pushed on to the product by a brush or roller. After labelling, the products move on and can be removed from the conveyor by the customer.

View Product