Pharmaceutical

Uniquely Engineered Labelling Solutions for the Pharmaceutical Industry

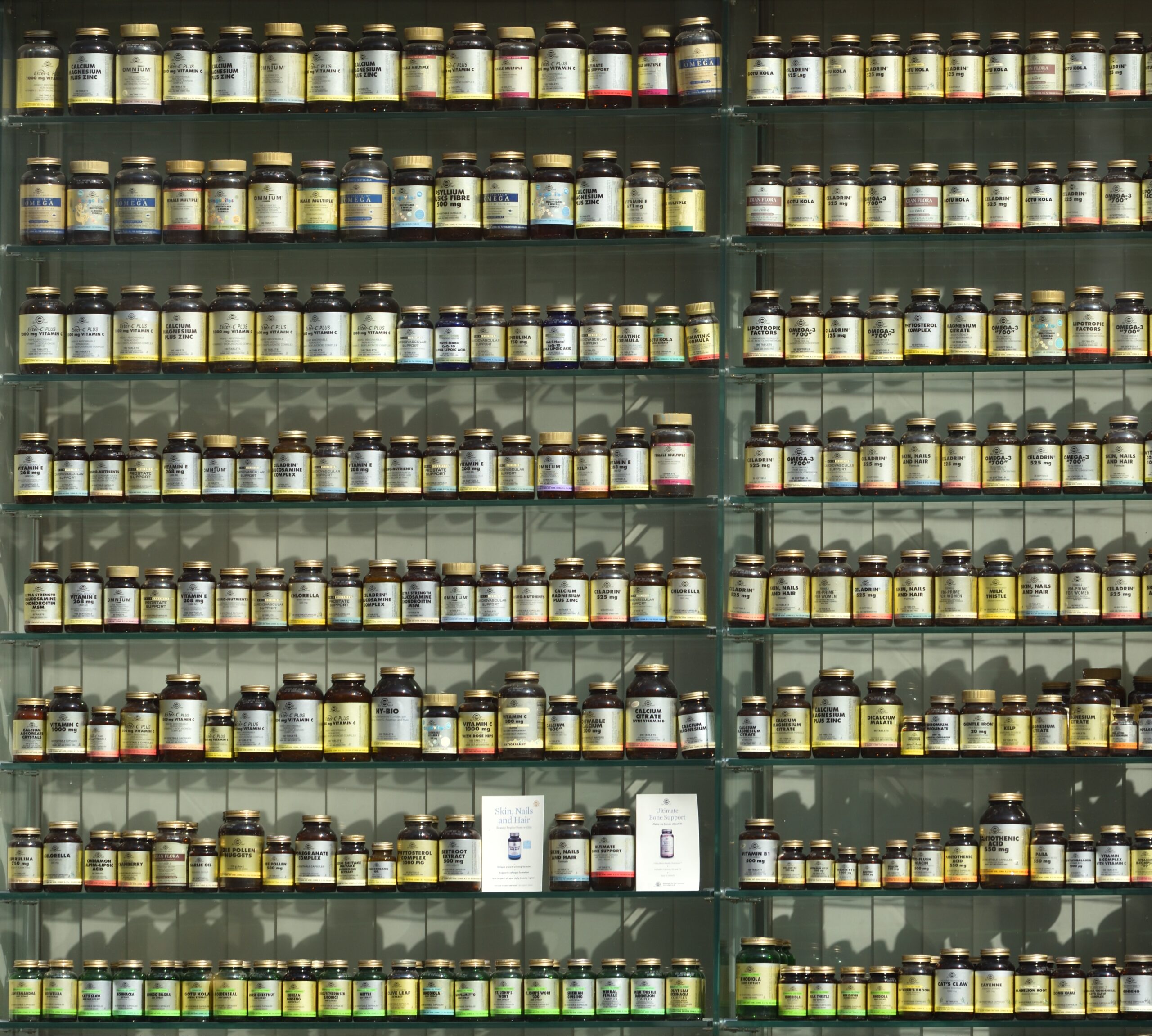

At Weber Packaging Solutions, we understand the critical importance of accurate medical labelling in the pharmaceutical industry. The potential risks of incorrect or inadequate labelling are simply too great to ignore, ranging from patient harm and legal liability to reputational damage and regulatory fines. That’s why we offer a wide range of labelling and coding solutions that are uniquely engineered to meet the specific needs and challenges of pharmaceutical manufacturers, packagers, and distributors.

- Secure, reliable, high-quality service

- Compliant labelling systems for regulatory bodies

- Traceability and counterfeit prevention solutions

- Precise product identification and print quality labelling

- Enhancing drug safety, compliance, and quality control

- Flexible integrated labelling solutions for existing medicine packaging lines.

Our Products

Counterfeit Prevention in Pharmaceuticals: Strategies and Solutions

We at Weber Packaging Solutions understand the importance of preventing counterfeit pharmaceuticals from entering the market. Counterfeit drugs pose a serious threat to public health, and can result in potentially lethal consequences. That’s why we offer a range of technologies and services that can help you ensure the authenticity and safety of your pharmaceutical products.

We at Weber Packaging Solutions understand the importance of preventing counterfeit pharmaceuticals from entering the market. Counterfeit drugs pose a serious threat to public health, and can result in potentially lethal consequences. That’s why we offer a range of technologies and services that can help you ensure the authenticity and safety of your pharmaceutical products.

The problem of counterfeit drugs is on the rise, with an estimated $200 billion worth of counterfeit medicines sold each year. These drugs can contain harmful or ineffective ingredients, and may be mislabeled, poorly manufactured, or even contaminated. In addition to the risks they pose to patients, counterfeit drugs can also damage a company’s reputation and bottom line.

To combat the counterfeit drug problem, regulatory bodies have developed guidelines and standards for track and trace systems and drug authentication. Compliance with these regulations is crucial for medical labels, and failure to comply can result in fines, recalls, and other penalties.

At Weber Packaging Solutions, we offer a range of technologies and services to help you prevent counterfeit pharmaceuticals from entering the market. Our authentication technologies such as holograms and watermarks can help distinguish genuine products from counterfeits. We also offer serialization and unique identification codes that can be used to track products throughout the supply chain and verify their authenticity. Our tamper-evident medical labels can help detect if a product has been opened or altered, and our supply chain management and tracking can help ensure that products are transported and stored properly with no gaps in the chain of custody.

We also offer medical labelling and coding solutions that can help you mark and identify your products with precision and accuracy, making it easier to distinguish genuine products from counterfeits. Our track and trace systems can be integrated into your production line to ensure compliance with regulations and standards for drug authentication. Our medicine packaging solutions can help protect your products from tampering and contamination.

With our expertise in counterfeit prevention in the pharmaceutical industry, you can trust Weber Packaging Solutions to help ensure the authenticity and safety of your products. Contact us today to learn more.

How Weber Packaging Solutions’ Track and Trace Systems Help Ensure Quality Control

In the pharmaceutical industry, quality control is of utmost importance. Counterfeit products and mix-ups could have lethal consequences, making the demands for traceability and counterfeit detection correspondingly high. Regulatory bodies across the world require strict adherence to their guidelines. At Weber Packaging Solutions, we understand the importance of precise medical labelling and coding in ensuring quality control, and our state-of-the-art production facility was built specifically to meet the demands of this highly regulated sector.

In the pharmaceutical industry, quality control is of utmost importance. Counterfeit products and mix-ups could have lethal consequences, making the demands for traceability and counterfeit detection correspondingly high. Regulatory bodies across the world require strict adherence to their guidelines. At Weber Packaging Solutions, we understand the importance of precise medical labelling and coding in ensuring quality control, and our state-of-the-art production facility was built specifically to meet the demands of this highly regulated sector.

One of the key solutions we offer for quality control is our track and trace systems. These systems provide a means of tracing products throughout the supply chain, ensuring that products are authentic and have not been tampered with. Our track and trace systems comply with all regulatory requirements in the pharmaceutical industry, and we are proud to offer our clients a solution that they can trust.

So, what exactly is track and trace? In short, track and trace is a means of assigning unique identification codes to products and tracing them throughout the supply chain. At Weber Packaging Solutions, we offer a range of track and trace solutions that can be tailored to meet the needs of our clients. Our systems are designed to ensure accuracy and reliability, and are easily integrated into medicine packaging facilities.

Our track and trace solutions are just one example of how we help our clients achieve exceptional results while adhering to regulations. With over 90 years of medical labelling knowledge and expertise, we understand the challenges faced by the pharmaceutical industry, and we are uniquely positioned to provide solutions that meet those challenges.

Contact us today to learn more about how we can help you achieve exceptional results while adhering to regulations.

Choosing the Right Labelling Technology for Pharmaceutical Products

When it comes to medical labelling, choosing the right technology is crucial. The medical labelling process not only provides essential information about the product but also ensures that it meets regulatory requirements and is safe for consumers. At Weber Packaging Solutions, we offer a range of medical labelling technologies, each with its own unique advantages and capabilities.

Direct Thermal Printing is a cost-effective solution that uses heat to create an image on the label. Thermal Transfer Printing, on the other hand, transfers the ink onto the label using a ribbon. Both technologies are suitable for printing product information and batch numbers, but they may not be the best options for medical labelling that requires high durability.

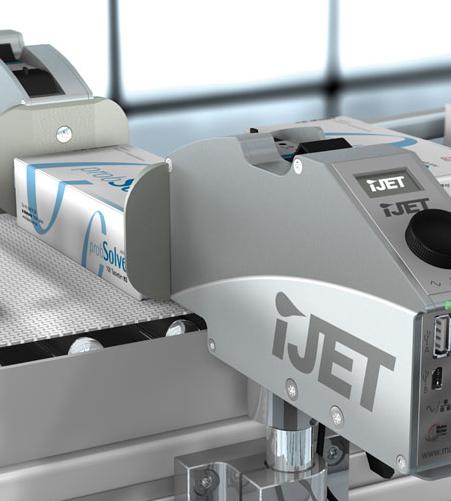

Inkjet Printing is a versatile technology that can be used for a range of applications, including printing barcodes, logos, and text on medical labels. Our inkjet printers are state-of-the-art systems, meeting the demands of the pharmaceutical industry’s printing, speed, and reliability requirements.

Inkjet Printing is a versatile technology that can be used for a range of applications, including printing barcodes, logos, and text on medical labels. Our inkjet printers are state-of-the-art systems, meeting the demands of the pharmaceutical industry’s printing, speed, and reliability requirements.

When choosing a medical labelling technology for your pharmaceutical products, it is important to consider various factors, such as cost, print quality and durability, regulatory compliance, production speed and efficiency, and integration with existing medicine packaging equipment. Our team of experts can help you choose the best technology for your specific needs and requirements.

We understand that different pharmaceutical products require different medical labelling technologies, and that is why we offer a range of solutions to meet your unique needs. Whether you need to medical labels for blister packs, vials and syringes, or bottles and containers, we have the expertise and equipment to provide you with the best medical labelling solution for your application. At Weber Packaging Solutions, we are committed to providing our customers with medical labelling solutions that are precise, reliable, and meet all regulatory requirements.

How Card Printers Enhance Security in Pharmaceutical Manufacturing

As a leader in medical labelling and coding solutions, Weber Packaging Solutions understands the importance of security in pharmaceutical label manufacturing. That’s why we offer a range of card printers that are designed to enhance security in access control systems, identity management, and record keeping.

As a leader in medical labelling and coding solutions, Weber Packaging Solutions understands the importance of security in pharmaceutical label manufacturing. That’s why we offer a range of card printers that are designed to enhance security in access control systems, identity management, and record keeping.

Our card printers are easy to use and offer a range of customization options, including full-color printing, encoding, and smart card personalization. With our card printers, you can create custom ID badges and access cards that are uniquely tailored to your facility’s needs.

Using card printers in your pharmaceutical manufacturing facility can help you achieve a higher level of security and control. With enhanced access control, you can ensure that only authorized personnel are able to access sensitive areas of your facility. Our card printers also enable you to improve identity management for employees and visitors, allowing you to easily track who is in your facility at any given time.

In addition to enhancing security, our card printers can also increase efficiency in record keeping and tracking. By creating custom cards with unique identifiers, you can easily track who has accessed certain areas of your facility, and when. This can be particularly useful in maintaining regulatory compliance and ensuring that your facility is operating in a safe and secure manner.

At Weber Packaging Solutions, we understand the unique challenges of pharmaceutical manufacturing, and our card printers are designed to meet those challenges head-on. With our extensive range of automatic and semi-automatic systems, we can provide you with a fully integrated medical labelling solution that meets your specific needs.

Our card printers are also designed to be fully compliant with all relevant regulations and standards for card printing in pharmaceutical manufacturing. We can help ensure that your facility is operating in compliance with all applicable regulations, while also providing you with the peace of mind that comes from knowing your facility is secure and well-protected.

The Benefits of Integrated Labelling Solutions for Medicine Packaging.

In the highly regulated pharmaceutical industry, accurate and reliable labelling and coding of products is essential to ensure safety, compliance, and quality control. However, pharmaceutical labels can pose unique challenges, from strict regulatory requirements to the need for counterfeit prevention and traceability demands.

In the highly regulated pharmaceutical industry, accurate and reliable labelling and coding of products is essential to ensure safety, compliance, and quality control. However, pharmaceutical labels can pose unique challenges, from strict regulatory requirements to the need for counterfeit prevention and traceability demands.

We understand these challenges and have a wide range of solutions and best practices to help you meet them. Our integrated medical labelling solutions are uniquely engineered to guarantee precise product identification and print quality. We provide hardware, software, equipment, and expertise to meet your medical labelling and coding needs, and our state-of-the-art production facility is purpose-built to meet the demands of the pharmaceutical sector.

Our comprehensive range of solutions includes utilizing the right medical labelling technology for different types of pharmaceutical products, implementing comprehensive track and trace systems for improved quality control, ensuring compliance with regulatory requirements through reliable labelling and coding, and investing in integrated labelling solutions for streamlined operations and enhanced efficiency.

One of the key benefits of our integrated medical labelling solutions is improved efficiency in medicine packaging. By automating the medical labelling process, you can streamline your operations and reduce the risk of errors, saving time and reducing costs.

In addition to improved efficiency, our integrated medical labelling solutions offer enhanced product identification and traceability. With our solutions, you can easily track your products from production to distribution, ensuring complete traceability and compliance with regulatory requirements.

Finally, our integrated medical labelling solutions can lead to cost savings for your business. By automating the medical labelling process and reducing the risk of errors, you can save time and reduce costs associated with product recalls and regulatory fines.

At Weber Packaging Solutions, we offer a wide range of hardware, software, equipment, and expertise to meet your medical labelling and coding needs. Our integrated labelling solutions are uniquely engineered to guarantee precise product identification and print quality. Contact us today to learn more about how our medical labelling solutions can help you achieve exceptional results while adhering to regulations in the pharmaceutical industry.