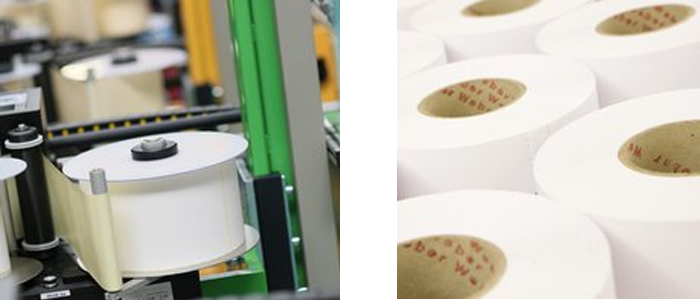

Blank labels

Blank labels are used in all industries for documentation and tracking and in logistics. The relevant labels are marked using the thermal direct or thermal transfer method; Weber also supplies the relevant printers for any conceivable purpose.

We offer you a broad spectrum of label variants, ensuring that you will always find the features tailor-made to suit your needs. These include, for instance, UV light-resistant, waterproof, recyclable and solvent-free labels and much more.

On customer request, we also produce labels on commission, even in small quantities and with customized text. With inventory number, barcode or serial numbering, for example. Every possible surface to be labelled is also considered. Feel free to ask us about our stock programme if you would like to order small quantities at short notice.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Zebra FS40 Fixed Industrial Scanner

Enable Performance. Inspire Potential. Experience The Difference.

Today more than ever, the increasing demands of international commerce and its global supply chain are pressuring companies to deliver more — and to do it faster. From manufacturing to logistics to the end customer, success is driven by the ability to quickly move and track the products that drive your business.

Address it all with Zebra’s FS40 Fixed Industrial Scanner designed to meet the comprehensive requirements of today’s production and delivery processes. The FS40 easily keeps pace with the fastest moving operations, enabling track-and-trace through the automatic and flawless decode of information on every part and package as it moves through production, storage and fulfilment — capturing even the most challenging barcodes. The result? Best-in-class production, warehousing, distribution and logistics processes that inspire businesses to reach their highest potential.

View ProductEASYMARK – Standard Wax

EASYMARK is the standard Weber wax ribbon which delivers consistent print

quality on any kind of paper label materials. It prints high density legible

barcodes and traceability data for short life labeling needs.

Markoprint Integra PP 108

The Markoprint Integra PP108 is the first inkjet printer with SEIKO printing technology and a circulating ink system. It features a POZIFLOW circulating ink system which prevents the accumulation of air in the nozzles and ensures a permanent, clean print image without missing print due to blocked nozzles. The system’s ink tank can be installed above, below, or at the same height as the print head without any problems. The new SEIKO printhead has a print height of 108 mm and achieves a remarkable speed of up to 150 meters per minute with a high resolution of 360 dpi.

Suited to Dual Colour Printing Applications such as Hazard Labelling, Dual Colour overprinting and Direct Printing Applications to corrugate, and web printing applications, the PP108 is the latest high end, economical Inkjet System using the latest Drop on Demand Printing Technology.

View ProductGeset 125 Horizontal Labelling System

The Geset 125 labelling system is used to label cylindrical products automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage of the labelling system. Care should be taken on accurate alignment of the products between the two freely mounted rollers of the roll conveyor. The side guide’s position the products flush with the outside edge of the roll conveyor.

The roll conveyor feeds the products to the labeller. There the label is applied with the part running forward onto the product and it is pushed by rotation and the back pressure of the wrapping unit onto the product. The back pressure of the wrapping unit (the speed of the wrapping unit is twice as fast as the speed of the base conveyor) enables the product in rotation. The roll conveyor forwards the finished labelled products to the outfeed. Here the products are removed manually or by the customer’s conveying system.

View Product