Zebra ZT510 Industrial Printer

ZEBRA ZT510 – NEXT-GENERATION PRINTING THAT IS BUDGET-FRIENDLY

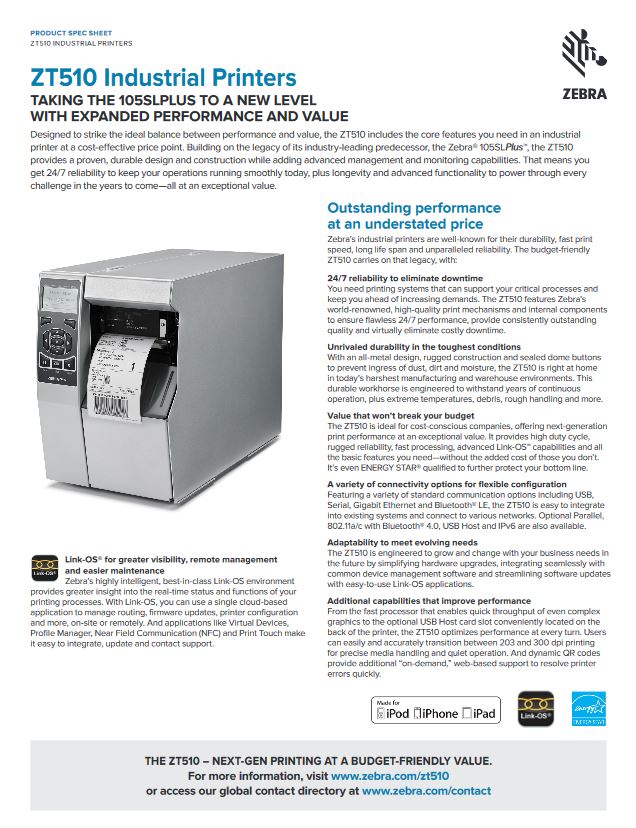

Designed to strike the ideal balance between performance and value, the Zebra ZT510 includes the core features you need in an industrial printer at a cost-effective price point.

ZEBRA ZT510 – NEXT-GENERATION PRINTING THAT IS BUDGET-FRIENDLY

Designed to strike the ideal balance between performance and value, Zebra’s ZT510 industrial printer includes the core features users need at a budget-friendly price point

ZEBRA ZT510 – PERFORMANCE AND VALUE

Designed to strike the ideal balance between performance and value, the Zebra ZT510 includes the core features you need in an industrial printer at a cost-effective price point.

ZEBRA ZT510 – EXCEPTIONAL PERFORMANCE IN THE HARSHEST CONDITIONS

Boost your productivity with printers that just won’t quit. The Zebra ZT510 builds on the legacy of its industry-leading predecessor, the 105SLPlus. Durable steel structural components can withstand years of abuse in extreme temperatures, dust, debris and other challenging industrial conditions, and meticulously engineered printing mechanisms provide 24/7 reliability to meet your high-volume production needs.

ZEBRA ZT510 – OPERATIONAL VISIBILITY, REMOTE MANAGEMENT AND FUTURE-READY ADAPTABILITY

Zebra’s cloud-accessible Link-OS software platform and managed services offerings give you total visibility and control over your printing systems, whether you’re onsite or across the globe. Plus, with two available communication slots, field installable media-handling options and optional USB Host for plug-and-play integration, it’s easy to stay ahead of your evolving business and technology needs, whatever they may be.

ZEBRA ZT510 – A VALUE THAT WON’T BREAK YOUR BUDGET

For cost-conscious decision makers, the ZT510 offers next-generation print performance at an exceptional value. It provides high-duty cycle, rugged reliability, fast processing, advanced Link-OS capabilities and all the basic features you need — without the added cost of those you don’t.

Key Applications:

- Asset Management

- Work-in-Process Tracking

- Packaging and Labeling

- Receiving/Shipping

- Cross Docking

- Compliance Labeling

| PRINT WIDTH 4.09″ / 104 mmMAXIMUM PRINT SPEED 12 ips / 305 mm per second

COMMUNICATION METHODS |

PRINT RESOLUTION 203 dpi / 8 dots per millimeter 300 dpi / 12 dots per millimeter (Optional)CONSTRUCTION All metal |

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

zt510-specification-sheet-a4-en-apprint-head-options-guide-en-us

ZT510_Comparison_Guide_A4

Geset 117 Top and Bottom Labelling System

The Geset 117 labelling system is used to label square products on the top and bottom side automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage on the labelling system. Care should be taken on accurate alignment of the products. It is essential that the products are forwarded separately to the applicator with a gap between each other.

When the light barrier is reached, an application trigger is tripped. Both label applicators apply then in Wipe On procedure a label onto the product. The label on top side is pushed on the product by a brush or roller. The label on bottom side is pushed on the product by the self-weight of the product. After labelling the products move on and can be removed from conveyor by the customer.

View ProductEASYMARK – Standard Wax

EASYMARK is the standard Weber wax ribbon which delivers consistent print

quality on any kind of paper label materials. It prints high density legible

barcodes and traceability data for short life labeling needs.

Zebra FS20 Fixed Industrial Scanner

An Easily Integratable Scanning Solution

The increasing demands of international commerce and its global supply chain are pressuring companies to deliver more — and to do it faster. From manufacturing to logistics to the end customer, success is driven by the ability to quickly move and track the products that drive your business.

Address it all with the compact Zebra FS20 Fixed Industrial Scanner. With the FS20, it’s easy to track and trace every item as it moves through production, storage and fulfilment. Scan barcodes on components moving through your assembly line to ensure the right part is used at the right time — and enable rapid targeted recalls of products that contain defective parts. Scan barcodes on items as they are placed on warehouse shelves to provide visibility into real time inventory. And scan barcodes when fulfilling orders to ensure the right items are sent to the right customer. Whatever you want to track and trace, the FS20 makes it easy.

View ProductULTRAPRINT – High durability resin

ULTRAPLATE is the standard resin ribbon from Weber. It is dedicated to

applications requiring a perfect printing quality and excellent mechanical

resistances. Its high versatility (it also prints on coated papers) and its

performances (sharpness, printing speed) have resulted in making

ULTRAPLATE a market reference.