Trident

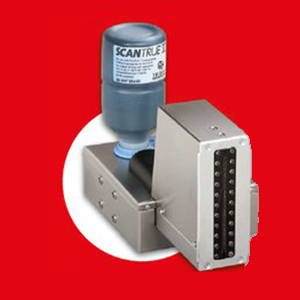

Trident is perfect for text, barcode and graphic marking on absorbent and smooth surfaces.It is easy to use, highly reliable and can reach printing speeds up to 60 meters per minute.

Click on the Direct Sales Button, and contact us today to order your Trident inkjet thermal inks.

- High reliability

Piezo-controlled graphic printing for industry-standard fonts, with almost unlimited number of rows.

- high printing speeds in barcode quality

up to 60 m/minute at 192 dpi (maximum 200 m/minute)

- good print image

based on perfected and proven Piezo technology

- simple operation

through integrated maintenance module

- unique flexibility

through the use of several Trident printheads

- Maximum 50 mm to 800 mm printing heights possible, as well as freely configurable layouts

- Multi-sided coding of packaging on two sides (top, side or at different production lines)

- virtually any porous surfaces can be marked, depending on ink type

- Topping up ink whilst in operation

- up to 5 mm distance from printhead to product surface enables marking of cartons with surface tolerances

- highly economical

- Best price-performance ratio in terms of ratio: cost of ink to area printed

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Geset 117 Top and Bottom Labelling System

The Geset 117 labelling system is used to label square products on the top and bottom side automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage on the labelling system. Care should be taken on accurate alignment of the products. It is essential that the products are forwarded separately to the applicator with a gap between each other.

When the light barrier is reached, an application trigger is tripped. Both label applicators apply then in Wipe On procedure a label onto the product. The label on top side is pushed on the product by a brush or roller. The label on bottom side is pushed on the product by the self-weight of the product. After labelling the products move on and can be removed from conveyor by the customer.

View ProductPLUSMARK – Premium Wax

PLUSMARK is the high performance wax ribbon from Weber. It offers all

the benefits of a general purpose wax ribbon with an improved print durability

and a capability to print on synthetic label materials.

Markoprint Integra Vivid

Unleash the Power of Modern Touch Operating Technology and an Innovative Swipe User Interface. Say Goodbye to Complicated Print Jobs and Say Hello to Effortless Operation of X1JET and PP Class Printing Systems. With the Freedom to Position the 7” High-Resolution HMI Color Display Anywhere You Choose, Prepare to Be Awed by the Ultimate Printing Flexibility and Innovation. Upgrade to integra Vivid Today and Embrace a New Era of Printing Excellence.

View ProductGeset 141 Semi Automatic Label Dispenser

The Geset 141 semi-automatic all-round labelling system is used for labelling small tins, bottles, jars etc. This solution was developed especially for companies requiring flexible labelling of small batches. Classical applications include the pharmaceutical and cosmetics industry and the food and beverage sector.

View Product