Zebra ZT200 series Printers

Zebra incorporated extensive customer feedback, as well as the legacy of its Stripe® and S4M™ printers, to create the new ZT200 series printers, which feature elegant space-saving design, effortless setup, intuitive user operation, and ease of service and maintenance. Whether you are adopting barcode technology for the first time or upgrading existing printer models, the ZT200 series is the right choice for a variety of labelling applications. These innovative new printers provide many user benefits.

The ZT200 series offers a streamlined design and smaller footprint that takes up less physical space than the Stripe and S4M models. ZT200 series printers require minimal operator training and benefit from tool-less standard component maintenance and a durable design to minimise service. Your IT staff will appreciate the backwards compatibility, since it allows for new printers to be up and running with minimal downtime.

The ZT200 series uses Zebra’s Link-OS™ environment: an open platform that pairs an operating system for smart Zebra devices with powerful software apps. AirWatch® Connector allows for simplified device management.The Print Station app quickly enables tablet- and smartphone-based printing. And with Cloud Connect, the ZT200 series printer can connect to the cloud directly and securely.

The ZT200 series has been designed for ease of use, versatility and outstanding value.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

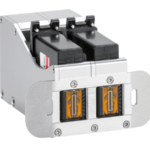

Zebra® ZT200™ seriesMarkoprint Shutter Printhead HP

Inkjet nozzles can clog and dry up in a dusty printing environment, which is typical in wood-processing enterprises and other sectors. This results in poorly printed images. Our Markoprint Shutter Printhead HP prevents dust from entering the ink cartridge or gathering on the nozzles. During a production halt, the printhead automatically retracts the cartridge and shuts the open nozzle plate. After being paused for even several days, it is instantly ready to print again.

View ProductX1Jet HP Premium MK2

The innovative Markoprint X1JET HP inkjet printer codes absorbent and semi-absorbent surfaces quickly, accurately and reliably. It is designed for a different range of applications in the food and beverage industry as well as the chemical and pharmaceutical industry. The controller and printer are combined in one single unit, making the system extremely compact.

View ProductMarkoprint NonStop Printing

To enable continuous marking in ongoing production, our Markoprint NonStopPrinting printhead holds two alternately printing cartridges. Because the other ink cartridge is printing on the same position, each ink cartridge can be changed, cleaned, or serviced without pausing the machine.

An intelligent automatism prevents both cartridges from going empty at the same time. The first cartridge will always print two consecutive print jobs, taking turns with the second cartridge, which will only print one. This sophisticated automatism avoids both cartridges from running out at the same time. This will keep the ink from drying out in both cartridges. When the cartridge with the larger print volumes is empty, a warning will show, and the other cartridge will continue printing until it is replaced. The new cartridge will print the lower quantities to allow for you to replace the “older” cartridge. A sophisticated workflow that will boost your efficiency and productivity.

View ProductPLUSMARK – Premium Wax

PLUSMARK is the high performance wax ribbon from Weber. It offers all

the benefits of a general purpose wax ribbon with an improved print durability

and a capability to print on synthetic label materials.