X1Jet MX

The Markoprint X1JET MX is an inkjet printer that runs independently. It’s ideal for coding large printing images directly on carton material in the food, beverage, chemical, and construction industries. On flat or absorbent surfaces, the MX Class piezo inkjet technology codes rapidly, correctly, and reliably.

The X1JET MX comes in three different styles: Compact, Vario, and Top. The print head on the Compact variant is fixed vertically. The Vario version’s print head may be rotated 90 degrees to the left for coding on ascending conveyor belts. The Top version codes to the packaging or product from above. True Type fonts are used to print text, logos, barcodes, and data matrix codes in the system.

The Markoprint X1JET MX makes printing simple with its 3-logic intuitive operation and LED status light. Data can be transferred via USB stick. It also has a maintenance station that includes a power supply.

Markoprint X1JET MX

Compact and well-prized piezo inkjet coder for large printing images

-

-

- Independent print system with Trident Piezo technology

-

-

-

- Cleaning station integrated with print system

-

-

-

- All-in-one – print head, ink system, cleaning station, control electronics and power supply

-

-

-

- Simple and intuitive 3-button operation with LED control lamps for user-friendly system controls

-

-

-

- Available as 50 or 100 mm print head

-

-

-

- As Compact, Top or Vario version

-

-

-

- With Scantrue ink

-

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

X1JET MX leafletInk Guide 2015

Markoprint Integra PP 108

The Markoprint Integra PP108 is the first inkjet printer with SEIKO printing technology and a circulating ink system. It features a POZIFLOW circulating ink system which prevents the accumulation of air in the nozzles and ensures a permanent, clean print image without missing print due to blocked nozzles. The system’s ink tank can be installed above, below, or at the same height as the print head without any problems. The new SEIKO printhead has a print height of 108 mm and achieves a remarkable speed of up to 150 meters per minute with a high resolution of 360 dpi.

Suited to Dual Colour Printing Applications such as Hazard Labelling, Dual Colour overprinting and Direct Printing Applications to corrugate, and web printing applications, the PP108 is the latest high end, economical Inkjet System using the latest Drop on Demand Printing Technology.

View ProductMarkoprint IP-Jet

The thermal inkjet printer IP-JET HP MK3 has been specifically designed for usage in dusty or damp situations. It is especially ideal for the food sector, as well as the plastics, pharmaceutical, and chemical industries, due to its IP65 protection level.

The IP-JET HP is a small inkjet printer with a printhead and control unit housed in one unit. Water and dust are kept out of the cartridge by sealing it and pressurizing it. The power supply features a waterproof connector, and the external connections’ connectors are secured with an IP67 rating. The printhead does not need to be covered or removed for wet cleaning, unlike many other printers on the market.

View ProductZebra FS20 Fixed Industrial Scanner

An Easily Integratable Scanning Solution

The increasing demands of international commerce and its global supply chain are pressuring companies to deliver more — and to do it faster. From manufacturing to logistics to the end customer, success is driven by the ability to quickly move and track the products that drive your business.

Address it all with the compact Zebra FS20 Fixed Industrial Scanner. With the FS20, it’s easy to track and trace every item as it moves through production, storage and fulfilment. Scan barcodes on components moving through your assembly line to ensure the right part is used at the right time — and enable rapid targeted recalls of products that contain defective parts. Scan barcodes on items as they are placed on warehouse shelves to provide visibility into real time inventory. And scan barcodes when fulfilling orders to ensure the right items are sent to the right customer. Whatever you want to track and trace, the FS20 makes it easy.

View ProductMarkoprint NonStop Printing

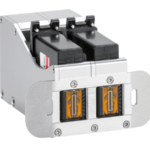

To enable continuous marking in ongoing production, our Markoprint NonStopPrinting printhead holds two alternately printing cartridges. Because the other ink cartridge is printing on the same position, each ink cartridge can be changed, cleaned, or serviced without pausing the machine.

An intelligent automatism prevents both cartridges from going empty at the same time. The first cartridge will always print two consecutive print jobs, taking turns with the second cartridge, which will only print one. This sophisticated automatism avoids both cartridges from running out at the same time. This will keep the ink from drying out in both cartridges. When the cartridge with the larger print volumes is empty, a warning will show, and the other cartridge will continue printing until it is replaced. The new cartridge will print the lower quantities to allow for you to replace the “older” cartridge. A sophisticated workflow that will boost your efficiency and productivity.

View Product