U-60 Label Dispenser

The Dispensa-Matic U-60 is ideal for dispensing pressure-sensitive labels from 0.375″ up to 6.0″ wide. Labels are peeled from their liner and presented to the user for easy grab and go labelling.

This semi-automatic electric label dispensing system is built to last using high-quality metal parts for years of service with little downtime. The U-60 is made in the USA and comes with a 3-year warranty.

U-60 Label Dispenser

The Dispensa-Matic U-60 Label Dispenser is a heavy-duty, semi-automatic electric label dispenser for labels from 0.375″ to 6.0″ wide x 0.375″ to any length. This label dispenser advances at over 7″ per second.

Features include:

Butt-cut or die-cut label compatible

Multiple row compatible

- Semi-automatic dispenser: pick, apply and repeat

- Label cartons, envelopes, brochures, bottles, bags, cans – anything that needs a label

- Side frames are made from the highest quality metals, then formed, countersunk, de burred and inspected

- Dispensing tables are formed out of aircraft-grade aluminium. The peel edge is hand-milled to spec within .001″

- Dispensing tables are polished with ultra-fine polishing compound so paper flows freely around the plate

- The U-60 motor is a shaded-pole AC motor

- Dispensa-Matic U-60 uses Micro-Switch branded switches, which are specifically designed to detect all kinds of labels: paper, Mylar, foil, holographic and clear; photo cell available

- International compatibility; motor is compatible for Europe and all other 220V 50/60hz

- Dimensions: 11″ x 13″ x 8″

- Weight: 13 lbs

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

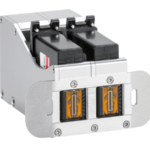

Markoprint NonStop Printing

To enable continuous marking in ongoing production, our Markoprint NonStopPrinting printhead holds two alternately printing cartridges. Because the other ink cartridge is printing on the same position, each ink cartridge can be changed, cleaned, or serviced without pausing the machine.

An intelligent automatism prevents both cartridges from going empty at the same time. The first cartridge will always print two consecutive print jobs, taking turns with the second cartridge, which will only print one. This sophisticated automatism avoids both cartridges from running out at the same time. This will keep the ink from drying out in both cartridges. When the cartridge with the larger print volumes is empty, a warning will show, and the other cartridge will continue printing until it is replaced. The new cartridge will print the lower quantities to allow for you to replace the “older” cartridge. A sophisticated workflow that will boost your efficiency and productivity.

View ProductMarkoprint Integra One ip LX

Unleash the Power of Proven Washdown Technology (IP Protection) for Seamless Performance in Complex and Demanding Applications. Experience High-Speed Printing and Effortless Operation with Up to 10 mm Print Distance. Discover Impressive Innovations, including a Patented Mechanism for Secure Ink/Printhead Unit Hold, Setting a New Standard in Printing Excellence.

View ProductMarkoprint Integra PP 108

The Markoprint Integra PP108 is the first inkjet printer with SEIKO printing technology and a circulating ink system. It features a POZIFLOW circulating ink system which prevents the accumulation of air in the nozzles and ensures a permanent, clean print image without missing print due to blocked nozzles. The system’s ink tank can be installed above, below, or at the same height as the print head without any problems. The new SEIKO printhead has a print height of 108 mm and achieves a remarkable speed of up to 150 meters per minute with a high resolution of 360 dpi.

Suited to Dual Colour Printing Applications such as Hazard Labelling, Dual Colour overprinting and Direct Printing Applications to corrugate, and web printing applications, the PP108 is the latest high end, economical Inkjet System using the latest Drop on Demand Printing Technology.

View ProductMarkoprint IP-Jet

The thermal inkjet printer IP-JET HP MK3 has been specifically designed for usage in dusty or damp situations. It is especially ideal for the food sector, as well as the plastics, pharmaceutical, and chemical industries, due to its IP65 protection level.

The IP-JET HP is a small inkjet printer with a printhead and control unit housed in one unit. Water and dust are kept out of the cartridge by sealing it and pressurizing it. The power supply features a waterproof connector, and the external connections’ connectors are secured with an IP67 rating. The printhead does not need to be covered or removed for wet cleaning, unlike many other printers on the market.

View Product