Special labels

Special labels by Weber Marking Systems meet the most diverse of requirements and have numerous specialized features, depending on their purpose.

We can offer, for instance:

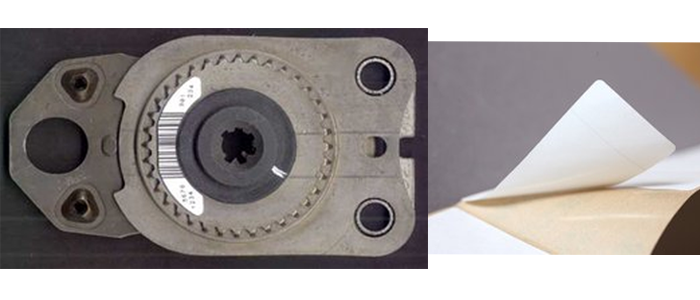

- water-, oil- and grease-resistant labels with extremely adhesive glue, e.g. for labelling of car tyres or cutting discs.

- Spunbonded fabric labels made of polyethylene continuous filament. These are resistant to water and many chemicals and solvents.

- Safety labels which, when removed, break a metallised polyester foil, leaving behind legible marking on the surface.

- Tags. These are robust, tear-proof and made of composite film – ideal for interior and exterior use. By dint of their paper coating, they are also perfect for customised marking at a later stage.

- Labels made of cast acrylate foil. The labelling material has been developed for marking where high demands are made on durability and resistance against extremely high temperatures. The labels withstand UV light and the weather; they are also resistant to solvents and retain their shape.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Markoprint Integra One ip LX

Unleash the Power of Proven Washdown Technology (IP Protection) for Seamless Performance in Complex and Demanding Applications. Experience High-Speed Printing and Effortless Operation with Up to 10 mm Print Distance. Discover Impressive Innovations, including a Patented Mechanism for Secure Ink/Printhead Unit Hold, Setting a New Standard in Printing Excellence.

View ProductMarkoprint Integra Quadro/Quadro²

The new Markoprint Integra Quadro/Quadro² print controller can control up to four inkjet printers or four print positions at the same time. This allows you to print on both sides of primary and secondary packaging on one or two separate production lines. There are also two separate printing methods that can be used in this process.

The Markoprint Integra Quadro/Quadro² can easily cope with limited space thanks to its slender design. Installation inside or directly at the industrial line is straightforward thanks to the different fixation options. It was designed specifically for installation in control panels and machinery.

View ProductGeset 112 Bottom Labelling System

The Geset 112 labelling system is used to label square products on the bottom side automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage on the labelling system. Care should be taken on accurate alignment of the products. It is essential that the products are forwarded separately to the applicator with a gap between each other.

When the light barrier is reached, an application trigger is tripped. The label applicator applies then in Wipe On procedure a label onto the product. The label on bottom side is pushed on the product by the self-weight of the product. After labelling the products move on and can be removed from conveyor by the customer.

View ProductZebra ZT510 Industrial Printer

ZEBRA ZT510 – NEXT-GENERATION PRINTING THAT IS BUDGET-FRIENDLY

Designed to strike the ideal balance between performance and value, the Zebra ZT510 includes the core features you need in an industrial printer at a cost-effective price point.

View Product