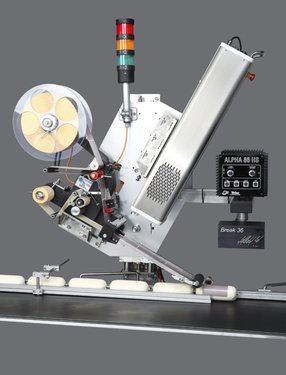

Laser Applicator: Alpha-Laser Label Applicator

The laser labeling solution comprises an Alpha label dispenser and a Solaris CO2 laser. The Alpha-Laser writes variable additional information such as best before dates, graphics or logistics data on pre-printed labels immediately before application.

Cost-effective and reliable labeling

The compact Alpha-Laser labels reliably and cost-effectively especially where large batches are processed and must be traced. This technology is ideally suited especially for harsh environments since the laser, as the printing unit, is considered virtually non-wearing compared to conventional printing methods.

The laser has a significantly longer service life by comparison and guarantees significantly higher availability, with no consumables or pressure bars. It ensures uninterrupted production. The laser writes all information – also batch and lot numbers – on any part of the label, with or across the direction of travel. The laser can write in black on laser-activable labels with a special finishing coat. No decomposition products are created and the labels are not damaged. The print is smear- and scratch-resistant.

The advantages of the Alpha-Laser in a nutshell:

- Any type of label made of paper or foil or foil-laminated material can be used

- Printing on a coating that can be activated exclusively by laser

- Printing of information in pre-printed color fields

- Writes codes and graphics

- No consumables

- Low maintenance

- Smear- and scratch-proof marking

- High marking speeds

- High process reliability and low running costs.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

24300Markoprint Integra Quadro/Quadro²

The new Markoprint Integra Quadro/Quadro² print controller can control up to four inkjet printers or four print positions at the same time. This allows you to print on both sides of primary and secondary packaging on one or two separate production lines. There are also two separate printing methods that can be used in this process.

The Markoprint Integra Quadro/Quadro² can easily cope with limited space thanks to its slender design. Installation inside or directly at the industrial line is straightforward thanks to the different fixation options. It was designed specifically for installation in control panels and machinery.

View ProductGeset 117 Top and Bottom Labelling System

The Geset 117 labelling system is used to label square products on the top and bottom side automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage on the labelling system. Care should be taken on accurate alignment of the products. It is essential that the products are forwarded separately to the applicator with a gap between each other.

When the light barrier is reached, an application trigger is tripped. Both label applicators apply then in Wipe On procedure a label onto the product. The label on top side is pushed on the product by a brush or roller. The label on bottom side is pushed on the product by the self-weight of the product. After labelling the products move on and can be removed from conveyor by the customer.

View ProductGeset 112 Bottom Labelling System

The Geset 112 labelling system is used to label square products on the bottom side automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage on the labelling system. Care should be taken on accurate alignment of the products. It is essential that the products are forwarded separately to the applicator with a gap between each other.

When the light barrier is reached, an application trigger is tripped. The label applicator applies then in Wipe On procedure a label onto the product. The label on bottom side is pushed on the product by the self-weight of the product. After labelling the products move on and can be removed from conveyor by the customer.

View ProductGeset 111 Top Labelling System

The Geset 111 labelling system is used to label square products on the top side automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage on the labelling system. Care should be taken on accurate alignment of the products. It is essential that the products are forwarded separately to the applicator with a gap between each other.

When the barrier is reached, an application trigger is tripped. The label applicator applies a label on the product in Wipe On procedure. The label on the top side is pushed on to the product by a brush or roller. After labelling, the products move on and can be removed from the conveyor by the customer.

View Product