Funai (Lexmark)

Funai (Lexmark) enables high resolution marking on any surface at very high speed.

Click on the Direct Sales Button, and contact us today to order your Funai (Lexmark) inkjet thermal inks.

- very high reliability under operational conditions

the cartridge and the complete printhead are exchanged simultaneously. This also guarantees consistent typeface quality.

- intelligent ink cartridge for increased coding reliability

ink type, manufacturer and ink content can be stored with the cartridge. The printer can therefore automatically be set to recognize the correct ink and other ink can be detected and blocked

Ink filling level detection guarantees timely detection of imminent cartridge replacement, assuring ongoing operation.

- very high printing speeds in barcode quality

up to 240 m/minute at 300 dpi (maximum 400 m/minute) with Dual Channel. There are two of every nozzle.

- extremely brilliant print image up to 900 dpi

using ink cartridges and thermo inkjets of consistent quality, achieved by ejecting tiny droplets from hundreds of minute nozzles at very high frequency and highly accurately positioned

- simple operation

the cartridges are clean and easy to handle. No special training or maintenance required.

- unique flexibility

by using several Funai printheads, max. printing heights of 12.7 to 100 mm are achieved, as well as freely configurable layouts.

- Multi-sided printing of packaging is possible

from top, bottom or side or also at different production lines.

- distances of up to 10 mm from printhead to product surface. This also enables flexible printing on convex and concave surfaces.

- virtually any porous and non-porous surfaces can be marked, depending on ink type.

- highly economical

low operating costs but also high availability through simple and clean ink exchange, zero maintenance, immediate write response and uninterrupted operation.

- simple installation

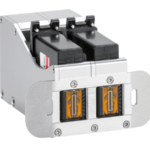

by dint of very compact design, with 2 different printhead types available

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

DURAPRINT – Wax resin

DURAPRINT is a very versatile, multi-purpose wax-resin ribbon.

It provides a higher level of resistances compared to standard wax ribbons and

prints small characters and barcodes with a high level of quality.

Geset 111 Top Labelling System

The Geset 111 labelling system is used to label square products on the top side automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage on the labelling system. Care should be taken on accurate alignment of the products. It is essential that the products are forwarded separately to the applicator with a gap between each other.

When the barrier is reached, an application trigger is tripped. The label applicator applies a label on the product in Wipe On procedure. The label on the top side is pushed on to the product by a brush or roller. After labelling, the products move on and can be removed from the conveyor by the customer.

View ProductMarkoprint NonStop Printing

To enable continuous marking in ongoing production, our Markoprint NonStopPrinting printhead holds two alternately printing cartridges. Because the other ink cartridge is printing on the same position, each ink cartridge can be changed, cleaned, or serviced without pausing the machine.

An intelligent automatism prevents both cartridges from going empty at the same time. The first cartridge will always print two consecutive print jobs, taking turns with the second cartridge, which will only print one. This sophisticated automatism avoids both cartridges from running out at the same time. This will keep the ink from drying out in both cartridges. When the cartridge with the larger print volumes is empty, a warning will show, and the other cartridge will continue printing until it is replaced. The new cartridge will print the lower quantities to allow for you to replace the “older” cartridge. A sophisticated workflow that will boost your efficiency and productivity.

View ProductMarkoprint IP-Jet

The thermal inkjet printer IP-JET HP MK3 has been specifically designed for usage in dusty or damp situations. It is especially ideal for the food sector, as well as the plastics, pharmaceutical, and chemical industries, due to its IP65 protection level.

The IP-JET HP is a small inkjet printer with a printhead and control unit housed in one unit. Water and dust are kept out of the cartridge by sealing it and pressurizing it. The power supply features a waterproof connector, and the external connections’ connectors are secured with an IP67 rating. The printhead does not need to be covered or removed for wet cleaning, unlike many other printers on the market.

View Product