Tamper Evident

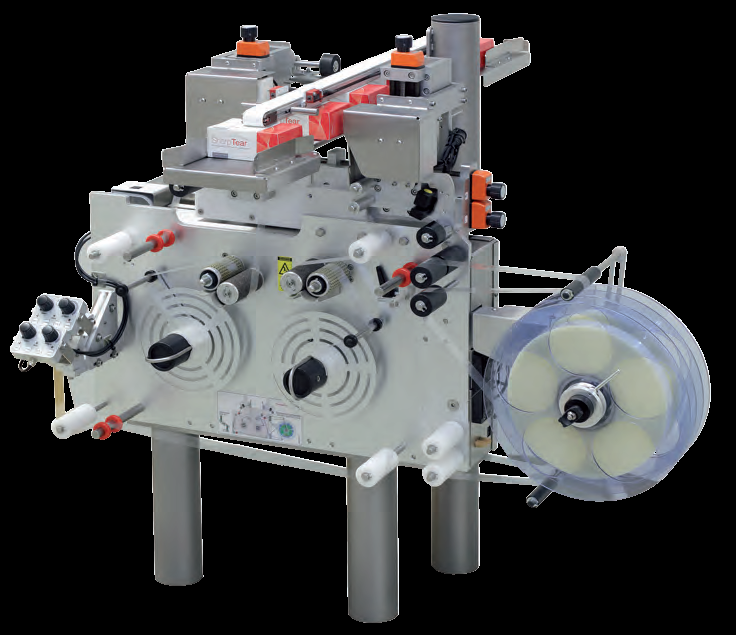

Compact label dispenser for protection against manipulation of pharmaceutical packaging.

The EU Directive 2011/62/EU promulgated in 2011 introduced legal framework requirements for a pan-European safety system for prevention of counterfeit medicines. A central component, which is also addressed in the pharmaceutical law, is a clear and secure marking system for database-backed traceability and tamper-proof sealing of all packaging. Bluhm System can offer a compact, efficient and reliable solution to this requirement. A compact labelling unit is integrated into existing data matrix stations or weighing systems. Self-adhesive label seals are applied on both sides of the flap openings of pharmaceutical packing. Perforation on the labels will expose manipulation by destruction of the labels. Depending on the packaging plant, labels are either dispensed after weighing or after an inkjet printer – e.g. the Markoprint series – has printed a sequential datamatrix code onto each package.

Following this, code and seal checking by a camera system is recommended. The package will be rejected if the marking is wrong or if a seal is applied incorrectly. Only OK products will leave the plant.

Special Features

- Sealing labelling for protection against counterfeits

- Two-sided corner labelling of folding boxes

- Highly compact design to allow integration into existing plant

- Output clocking up to 300 items per minute

- Stepper motor driven applicator

- Short set-up times when switching to other product formats

- Processing of transparent, perforated labels

- Speed-independent labelling via Tamp-Wipe-On method

- Dual label roll unwinding

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Tamper Evident WeberMarkoprint IP-Jet

The thermal inkjet printer IP-JET HP MK3 has been specifically designed for usage in dusty or damp situations. It is especially ideal for the food sector, as well as the plastics, pharmaceutical, and chemical industries, due to its IP65 protection level.

The IP-JET HP is a small inkjet printer with a printhead and control unit housed in one unit. Water and dust are kept out of the cartridge by sealing it and pressurizing it. The power supply features a waterproof connector, and the external connections’ connectors are secured with an IP67 rating. The printhead does not need to be covered or removed for wet cleaning, unlike many other printers on the market.

View ProductMarkoprint Integra One ip LX

Unleash the Power of Proven Washdown Technology (IP Protection) for Seamless Performance in Complex and Demanding Applications. Experience High-Speed Printing and Effortless Operation with Up to 10 mm Print Distance. Discover Impressive Innovations, including a Patented Mechanism for Secure Ink/Printhead Unit Hold, Setting a New Standard in Printing Excellence.

View ProductGeset 117 Top and Bottom Labelling System

The Geset 117 labelling system is used to label square products on the top and bottom side automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage on the labelling system. Care should be taken on accurate alignment of the products. It is essential that the products are forwarded separately to the applicator with a gap between each other.

When the light barrier is reached, an application trigger is tripped. Both label applicators apply then in Wipe On procedure a label onto the product. The label on top side is pushed on the product by a brush or roller. The label on bottom side is pushed on the product by the self-weight of the product. After labelling the products move on and can be removed from conveyor by the customer.

View ProductGeset 112 Bottom Labelling System

The Geset 112 labelling system is used to label square products on the bottom side automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage on the labelling system. Care should be taken on accurate alignment of the products. It is essential that the products are forwarded separately to the applicator with a gap between each other.

When the light barrier is reached, an application trigger is tripped. The label applicator applies then in Wipe On procedure a label onto the product. The label on bottom side is pushed on the product by the self-weight of the product. After labelling the products move on and can be removed from conveyor by the customer.

View Product