Special labels

Special labels by Weber Marking Systems meet the most diverse of requirements and have numerous specialized features, depending on their purpose.

We can offer, for instance:

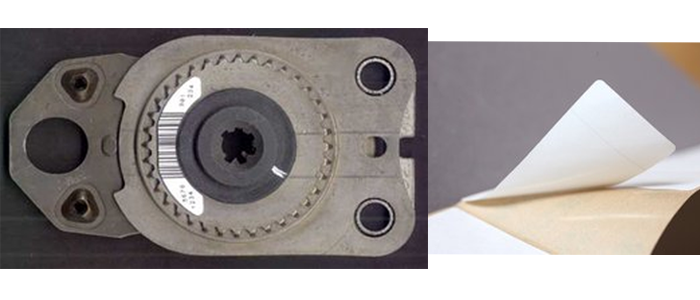

- water-, oil- and grease-resistant labels with extremely adhesive glue, e.g. for labelling of car tyres or cutting discs.

- Spunbonded fabric labels made of polyethylene continuous filament. These are resistant to water and many chemicals and solvents.

- Safety labels which, when removed, break a metallised polyester foil, leaving behind legible marking on the surface.

- Tags. These are robust, tear-proof and made of composite film – ideal for interior and exterior use. By dint of their paper coating, they are also perfect for customised marking at a later stage.

- Labels made of cast acrylate foil. The labelling material has been developed for marking where high demands are made on durability and resistance against extremely high temperatures. The labels withstand UV light and the weather; they are also resistant to solvents and retain their shape.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

Zebra FS70 Fixed Industrial Scanner

Today more than ever, the increasing demands of international commerce and its global supply chain are pressuring companies to deliver more — and to do it faster. From manufacturing to logistics to the end customer, success is driven by the ability to quickly move and track the products that drive your business.

The FS70 Fixed Industrial Scanner is your configurable and customisable solution. Easily keep pace with your business, enabling quality control and track-and-trace of every part and package as it moves through production, storage and fulfilment. Whether you need a high-powered lens to read a very small barcode from a long distance, or a wide-angle lens to capture barcodes on extremely large parts, the FS70 addresses it all. C-mount external lenses allow you to achieve the working range and field of view your application and environment requires. And compatibility with virtually any external lighting solution ensures reading of the most challenging barcodes — even low-contrast direct part marks or those printed on curved or reflective surfaces. The result? Best-in-class production, warehousing, distribution and logistics processes that inspire your business to reach its highest potential.

View Product

Zebra FS20 Fixed Industrial Scanner

An Easily Integratable Scanning Solution

The increasing demands of international commerce and its global supply chain are pressuring companies to deliver more — and to do it faster. From manufacturing to logistics to the end customer, success is driven by the ability to quickly move and track the products that drive your business.

Address it all with the compact Zebra FS20 Fixed Industrial Scanner. With the FS20, it’s easy to track and trace every item as it moves through production, storage and fulfilment. Scan barcodes on components moving through your assembly line to ensure the right part is used at the right time — and enable rapid targeted recalls of products that contain defective parts. Scan barcodes on items as they are placed on warehouse shelves to provide visibility into real time inventory. And scan barcodes when fulfilling orders to ensure the right items are sent to the right customer. Whatever you want to track and trace, the FS20 makes it easy.

View ProductULTRAPRINT – High durability resin

ULTRAPLATE is the standard resin ribbon from Weber. It is dedicated to

applications requiring a perfect printing quality and excellent mechanical

resistances. Its high versatility (it also prints on coated papers) and its

performances (sharpness, printing speed) have resulted in making

ULTRAPLATE a market reference.

Geset 125 Horizontal Labelling System

The Geset 125 labelling system is used to label cylindrical products automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage of the labelling system. Care should be taken on accurate alignment of the products between the two freely mounted rollers of the roll conveyor. The side guide’s position the products flush with the outside edge of the roll conveyor.

The roll conveyor feeds the products to the labeller. There the label is applied with the part running forward onto the product and it is pushed by rotation and the back pressure of the wrapping unit onto the product. The back pressure of the wrapping unit (the speed of the wrapping unit is twice as fast as the speed of the base conveyor) enables the product in rotation. The roll conveyor forwards the finished labelled products to the outfeed. Here the products are removed manually or by the customer’s conveying system.

View Product