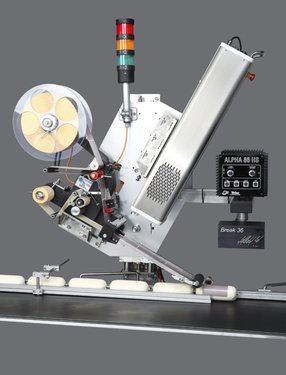

Laser Applicator: Alpha-Laser Label Applicator

The laser labeling solution comprises an Alpha label dispenser and a Solaris CO2 laser. The Alpha-Laser writes variable additional information such as best before dates, graphics or logistics data on pre-printed labels immediately before application.

Cost-effective and reliable labeling

The compact Alpha-Laser labels reliably and cost-effectively especially where large batches are processed and must be traced. This technology is ideally suited especially for harsh environments since the laser, as the printing unit, is considered virtually non-wearing compared to conventional printing methods.

The laser has a significantly longer service life by comparison and guarantees significantly higher availability, with no consumables or pressure bars. It ensures uninterrupted production. The laser writes all information – also batch and lot numbers – on any part of the label, with or across the direction of travel. The laser can write in black on laser-activable labels with a special finishing coat. No decomposition products are created and the labels are not damaged. The print is smear- and scratch-resistant.

The advantages of the Alpha-Laser in a nutshell:

- Any type of label made of paper or foil or foil-laminated material can be used

- Printing on a coating that can be activated exclusively by laser

- Printing of information in pre-printed color fields

- Writes codes and graphics

- No consumables

- Low maintenance

- Smear- and scratch-proof marking

- High marking speeds

- High process reliability and low running costs.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

24300Zebra FS70 Fixed Industrial Scanner

Today more than ever, the increasing demands of international commerce and its global supply chain are pressuring companies to deliver more — and to do it faster. From manufacturing to logistics to the end customer, success is driven by the ability to quickly move and track the products that drive your business.

The FS70 Fixed Industrial Scanner is your configurable and customisable solution. Easily keep pace with your business, enabling quality control and track-and-trace of every part and package as it moves through production, storage and fulfilment. Whether you need a high-powered lens to read a very small barcode from a long distance, or a wide-angle lens to capture barcodes on extremely large parts, the FS70 addresses it all. C-mount external lenses allow you to achieve the working range and field of view your application and environment requires. And compatibility with virtually any external lighting solution ensures reading of the most challenging barcodes — even low-contrast direct part marks or those printed on curved or reflective surfaces. The result? Best-in-class production, warehousing, distribution and logistics processes that inspire your business to reach its highest potential.

View Product

Markoprint Integra Vivid

Unleash the Power of Modern Touch Operating Technology and an Innovative Swipe User Interface. Say Goodbye to Complicated Print Jobs and Say Hello to Effortless Operation of X1JET and PP Class Printing Systems. With the Freedom to Position the 7” High-Resolution HMI Color Display Anywhere You Choose, Prepare to Be Awed by the Ultimate Printing Flexibility and Innovation. Upgrade to integra Vivid Today and Embrace a New Era of Printing Excellence.

View ProductMarkoprint Integra PP RAZR

Experience Effortless High-Resolution Printing: Introducing the Integra PP RAZR with Cutting-Edge Technology. Print Up to 34mm High on Virtually Any Product Surface with Ease. Be Amazed by the Permanent Print Head’s Impressive Resolution, Lightning-Fast Speed, and Integrated Redundancy. Plus, its Compact Design Ensures Seamless Placement in Any Production Facility.

View ProductGeset 141 Semi Automatic Label Dispenser

The Geset 141 semi-automatic all-round labelling system is used for labelling small tins, bottles, jars etc. This solution was developed especially for companies requiring flexible labelling of small batches. Classical applications include the pharmaceutical and cosmetics industry and the food and beverage sector.

View Product