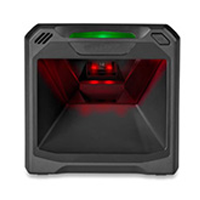

Symbol DS7708 Scanner

Easy to Deploy, High-Performance, “Can’t Miss” On-Counter Scanning

When it comes to on-counter scanning, the DS7708 scanner offers a feature set that puts it at the top of its class for performance, ease of use, easy deployment and total cost of ownership. With a large field of view that is over 50 percent larger than the competition, the DS7708 easily captures bar codes regardless of where they are located on an item. No matter what type of bar codes appear at the POS, the DS7708 can scan them all: 1D, 2D, printed and electronic.

Innovative Features of the DS7708 Scanner

Scan virtually any type of bar code

First time, every time capture of 1D and 2D bar codes displayed on mobile devices or printed on paper labels—even if they are damaged, poorly printed, or dirty.

PRZM intelligent imaging

The DS7708 resets the bar for 2D imaging by improving decode performance and snappiness, while dramatically improving user experience, user productivity, throughput and customer wait times.

Largest field of view in its class

A field of view that is over 50 percent larger than competitive 2D imagers enables easy capture of bar codes, regardless of where they are located on an item. Scanning is truly second nature—no need to orient an item to capture the bar code.

Superior durability

Multiple features make the DS7708 the most durable device in its class: the recessed scan window prevents marks and scratches that can degrade scanning performance and lifecycle. In addition, the electronics are located in the top area of the DS7708 to prevent damage and protect uptime in the event of a spill.

Virtually invisible illumination

The LEDs are recessed behind the scan window, where they are barely visible and won’t disturb customers or cashiers.

Power through a single USB port

No additional power supply is required when connecting via USB, reducing accessory, installation and management costs.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

DS7708_SSGeset 141 Semi Automatic Label Dispenser

The Geset 141 semi-automatic all-round labelling system is used for labelling small tins, bottles, jars etc. This solution was developed especially for companies requiring flexible labelling of small batches. Classical applications include the pharmaceutical and cosmetics industry and the food and beverage sector.

View Product

Markoprint Integra Quadro/Quadro²

The new Markoprint Integra Quadro/Quadro² print controller can control up to four inkjet printers or four print positions at the same time. This allows you to print on both sides of primary and secondary packaging on one or two separate production lines. There are also two separate printing methods that can be used in this process.

The Markoprint Integra Quadro/Quadro² can easily cope with limited space thanks to its slender design. Installation inside or directly at the industrial line is straightforward thanks to the different fixation options. It was designed specifically for installation in control panels and machinery.

View ProductGeset 117 Top and Bottom Labelling System

The Geset 117 labelling system is used to label square products on the top and bottom side automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage on the labelling system. Care should be taken on accurate alignment of the products. It is essential that the products are forwarded separately to the applicator with a gap between each other.

When the light barrier is reached, an application trigger is tripped. Both label applicators apply then in Wipe On procedure a label onto the product. The label on top side is pushed on the product by a brush or roller. The label on bottom side is pushed on the product by the self-weight of the product. After labelling the products move on and can be removed from conveyor by the customer.

View ProductX1Jet HP Premium MK2

The innovative Markoprint X1JET HP inkjet printer codes absorbent and semi-absorbent surfaces quickly, accurately and reliably. It is designed for a different range of applications in the food and beverage industry as well as the chemical and pharmaceutical industry. The controller and printer are combined in one single unit, making the system extremely compact.

View Product