I-Class Mark II

We made the best better.

Datamax-O’Neil’s I-Class revolutionized the barcode printer industry with its award winning modular design, field installable options and rugged reliability.

For the past several years, resellers have named the I-Class the “best channel product” in some of the industry’s largest third-party surveys. Now we’ve raised the bar even higher, with the redesigned I-Class Mark II.

Offering the fastest processor, largest memory and widest selection of communication ports available in a mid-range printer, the I-Class Mark II provides lower operating costs and flawless print quality. For applications as diverse as shipping and receiving, product identification, pharmacy labeling and asset tracking, the I-Class Mark II will maintain its reputation for providing outstanding for performance, reliability and value.

Specifications at-a-glance:

- Direct thermal, thermal transfer (optional)

- 4.16” [105.7 mm] maximum print width

- 203 dpi [8 dots/mm], 300 dpi [12 dots/mm], 600 dpi [24 dots/mm] optional resolution

- 12 ips [304 mm/s] maximum print speed

- Ethernet wired LAN 10/100, W-LAN with WPA2 security protocol, 2 USB Host Ports and SDIO, GPIO interface card

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

I Class MII PrintersMarkoprint NonStop Printing

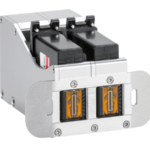

To enable continuous marking in ongoing production, our Markoprint NonStopPrinting printhead holds two alternately printing cartridges. Because the other ink cartridge is printing on the same position, each ink cartridge can be changed, cleaned, or serviced without pausing the machine.

An intelligent automatism prevents both cartridges from going empty at the same time. The first cartridge will always print two consecutive print jobs, taking turns with the second cartridge, which will only print one. This sophisticated automatism avoids both cartridges from running out at the same time. This will keep the ink from drying out in both cartridges. When the cartridge with the larger print volumes is empty, a warning will show, and the other cartridge will continue printing until it is replaced. The new cartridge will print the lower quantities to allow for you to replace the “older” cartridge. A sophisticated workflow that will boost your efficiency and productivity.

View ProductZebra FS70 Fixed Industrial Scanner

Today more than ever, the increasing demands of international commerce and its global supply chain are pressuring companies to deliver more — and to do it faster. From manufacturing to logistics to the end customer, success is driven by the ability to quickly move and track the products that drive your business.

The FS70 Fixed Industrial Scanner is your configurable and customisable solution. Easily keep pace with your business, enabling quality control and track-and-trace of every part and package as it moves through production, storage and fulfilment. Whether you need a high-powered lens to read a very small barcode from a long distance, or a wide-angle lens to capture barcodes on extremely large parts, the FS70 addresses it all. C-mount external lenses allow you to achieve the working range and field of view your application and environment requires. And compatibility with virtually any external lighting solution ensures reading of the most challenging barcodes — even low-contrast direct part marks or those printed on curved or reflective surfaces. The result? Best-in-class production, warehousing, distribution and logistics processes that inspire your business to reach its highest potential.

View Product

Markoprint ZTV HP

The Markoprint ZTV HP is a Central Ink Supply (CIS) system stores up to 400ml of ink for Markoprint HP Class inkjet printing systems such as the Markoprint integra One, Markoprint X2JET / X4JET, and Markoprint integra Quadro.

The large ink tank prevents frequent cartridge replacements from lowering your Overall Equipment Effectiveness (OEE). It can hold up to four single HP cartridges repaying you rapidly thanks to reduced ink prices. For non-interrupted production, the system can be paired with our NonStopPrinting printhead. Using an interface directly on the cartridge, current ink filling levels are monitored in real time. When the levels in the bulk tank fall below a certain threshold, a valve to the bulk tank opens and automatically refills it.

View ProductZebra FS20 Fixed Industrial Scanner

An Easily Integratable Scanning Solution

The increasing demands of international commerce and its global supply chain are pressuring companies to deliver more — and to do it faster. From manufacturing to logistics to the end customer, success is driven by the ability to quickly move and track the products that drive your business.

Address it all with the compact Zebra FS20 Fixed Industrial Scanner. With the FS20, it’s easy to track and trace every item as it moves through production, storage and fulfilment. Scan barcodes on components moving through your assembly line to ensure the right part is used at the right time — and enable rapid targeted recalls of products that contain defective parts. Scan barcodes on items as they are placed on warehouse shelves to provide visibility into real time inventory. And scan barcodes when fulfilling orders to ensure the right items are sent to the right customer. Whatever you want to track and trace, the FS20 makes it easy.

View Product