Model 5300 Series Pail/Drum Label Printer-Applicator

The fully-automatic system that quickly and accurately prints and applies labels to pails or drums on the production line.

• Fully automatic pail/drum labelling system

• Ideal for rough production conditions

• High-grade label printing in a single operation

• Prints and applies labels up to 7″ x 14″

• Labels up to 30 products per minute

• Print resolution up to 600 dpi

• All conventional data interfaces

• Service interval display

• Display controller for simple operation

• Easy integration

• CE certification

Model 5300 Pail/Drum Label Printer-Applicator

Weber has designed and engineered a unique label printing and application solution that features flexibility, quality and efficiency.

Weber’s Model 5300 Pail/Drum Labelling System quickly and consistently prints and applies perfectly positioned labels to the outer circumference of the product. It optimizes the product identification process to provide a positive impression on consumers, thanks to accurate label placement that ensures strong brand impact. The labels are applied straight and consistent every time.

The system prints top-quality labels up to 7″ x 14″ with very high-resolution text, bar codes and/or graphic images. The durable construction of this unique labelling solution makes it suitable for use in all sorts of production environments.

Pails or drums can be properly labelled even amid changing product identification requirements, and variable products and information can be accommodated without wasting labels. The Model 5300 Pail/Drum Labelling System is versatile enough to communicate via existing data controllers or interfaces.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

5300Geset 125 Horizontal Labelling System

The Geset 125 labelling system is used to label cylindrical products automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage of the labelling system. Care should be taken on accurate alignment of the products between the two freely mounted rollers of the roll conveyor. The side guide’s position the products flush with the outside edge of the roll conveyor.

The roll conveyor feeds the products to the labeller. There the label is applied with the part running forward onto the product and it is pushed by rotation and the back pressure of the wrapping unit onto the product. The back pressure of the wrapping unit (the speed of the wrapping unit is twice as fast as the speed of the base conveyor) enables the product in rotation. The roll conveyor forwards the finished labelled products to the outfeed. Here the products are removed manually or by the customer’s conveying system.

View ProductMarkoprint Integra Ultimate

The innovative Integra Ultimate thermal inkjet printer not only provides IP65 protection against dust and moisture, but it also closes and cleans the nozzle plate at each pause. This system ensures that the printing is always clean, with faultless results even after extended breaks. As a result, the ink cartridges’ open times are multiplied many times. Two HP Class thermal inkjet ink cartridges can be used with the print head. As a result, the system produces beautiful prints with a maximum height of 25 mm.

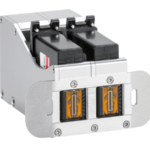

View ProductMarkoprint NonStop Printing

To enable continuous marking in ongoing production, our Markoprint NonStopPrinting printhead holds two alternately printing cartridges. Because the other ink cartridge is printing on the same position, each ink cartridge can be changed, cleaned, or serviced without pausing the machine.

An intelligent automatism prevents both cartridges from going empty at the same time. The first cartridge will always print two consecutive print jobs, taking turns with the second cartridge, which will only print one. This sophisticated automatism avoids both cartridges from running out at the same time. This will keep the ink from drying out in both cartridges. When the cartridge with the larger print volumes is empty, a warning will show, and the other cartridge will continue printing until it is replaced. The new cartridge will print the lower quantities to allow for you to replace the “older” cartridge. A sophisticated workflow that will boost your efficiency and productivity.

View ProductMarkoprint Integra One ip LX

Unleash the Power of Proven Washdown Technology (IP Protection) for Seamless Performance in Complex and Demanding Applications. Experience High-Speed Printing and Effortless Operation with Up to 10 mm Print Distance. Discover Impressive Innovations, including a Patented Mechanism for Secure Ink/Printhead Unit Hold, Setting a New Standard in Printing Excellence.

View Product