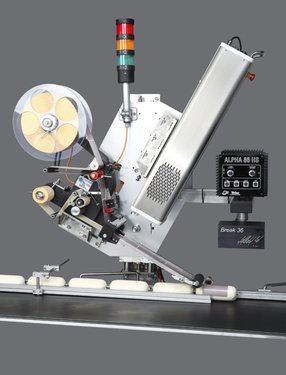

Laser Applicator: Alpha-Laser Label Applicator

The laser labeling solution comprises an Alpha label dispenser and a Solaris CO2 laser. The Alpha-Laser writes variable additional information such as best before dates, graphics or logistics data on pre-printed labels immediately before application.

Cost-effective and reliable labeling

The compact Alpha-Laser labels reliably and cost-effectively especially where large batches are processed and must be traced. This technology is ideally suited especially for harsh environments since the laser, as the printing unit, is considered virtually non-wearing compared to conventional printing methods.

The laser has a significantly longer service life by comparison and guarantees significantly higher availability, with no consumables or pressure bars. It ensures uninterrupted production. The laser writes all information – also batch and lot numbers – on any part of the label, with or across the direction of travel. The laser can write in black on laser-activable labels with a special finishing coat. No decomposition products are created and the labels are not damaged. The print is smear- and scratch-resistant.

The advantages of the Alpha-Laser in a nutshell:

- Any type of label made of paper or foil or foil-laminated material can be used

- Printing on a coating that can be activated exclusively by laser

- Printing of information in pre-printed color fields

- Writes codes and graphics

- No consumables

- Low maintenance

- Smear- and scratch-proof marking

- High marking speeds

- High process reliability and low running costs.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

24300Geset 112 Bottom Labelling System

The Geset 112 labelling system is used to label square products on the bottom side automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage on the labelling system. Care should be taken on accurate alignment of the products. It is essential that the products are forwarded separately to the applicator with a gap between each other.

When the light barrier is reached, an application trigger is tripped. The label applicator applies then in Wipe On procedure a label onto the product. The label on bottom side is pushed on the product by the self-weight of the product. After labelling the products move on and can be removed from conveyor by the customer.

View ProductMarkoprint Shutter Printhead HP

Inkjet nozzles can clog and dry up in a dusty printing environment, which is typical in wood-processing enterprises and other sectors. This results in poorly printed images. Our Markoprint Shutter Printhead HP prevents dust from entering the ink cartridge or gathering on the nozzles. During a production halt, the printhead automatically retracts the cartridge and shuts the open nozzle plate. After being paused for even several days, it is instantly ready to print again.

View ProductZebra FS40 Fixed Industrial Scanner

Enable Performance. Inspire Potential. Experience The Difference.

Today more than ever, the increasing demands of international commerce and its global supply chain are pressuring companies to deliver more — and to do it faster. From manufacturing to logistics to the end customer, success is driven by the ability to quickly move and track the products that drive your business.

Address it all with Zebra’s FS40 Fixed Industrial Scanner designed to meet the comprehensive requirements of today’s production and delivery processes. The FS40 easily keeps pace with the fastest moving operations, enabling track-and-trace through the automatic and flawless decode of information on every part and package as it moves through production, storage and fulfilment — capturing even the most challenging barcodes. The result? Best-in-class production, warehousing, distribution and logistics processes that inspire businesses to reach their highest potential.

View ProductMarkoprint Integra One

Labeling systems are not always easy to integrate into preexisting production lines. The Markoprint Integra One can be easily integrated into production processes thanks to its compact dimensions of 186 x 86 x 98 mm. The printing system has a display for data entry as well as system settings modification and verification. This information can also be viewed from mobile devices if the WLAN version is selected.

Inkjet printers should be properly protected if they are subjected to harsh manufacturing circumstances. In addition, the Markoprint integra One ip has an IP 65 protection rating. As a result, it’s ideal for use in the food industry.

View Product