Symbol DS7708 Scanner

Easy to Deploy, High-Performance, “Can’t Miss” On-Counter Scanning

When it comes to on-counter scanning, the DS7708 scanner offers a feature set that puts it at the top of its class for performance, ease of use, easy deployment and total cost of ownership. With a large field of view that is over 50 percent larger than the competition, the DS7708 easily captures bar codes regardless of where they are located on an item. No matter what type of bar codes appear at the POS, the DS7708 can scan them all: 1D, 2D, printed and electronic.

Innovative Features of the DS7708 Scanner

Scan virtually any type of bar code

First time, every time capture of 1D and 2D bar codes displayed on mobile devices or printed on paper labels—even if they are damaged, poorly printed, or dirty.

PRZM intelligent imaging

The DS7708 resets the bar for 2D imaging by improving decode performance and snappiness, while dramatically improving user experience, user productivity, throughput and customer wait times.

Largest field of view in its class

A field of view that is over 50 percent larger than competitive 2D imagers enables easy capture of bar codes, regardless of where they are located on an item. Scanning is truly second nature—no need to orient an item to capture the bar code.

Superior durability

Multiple features make the DS7708 the most durable device in its class: the recessed scan window prevents marks and scratches that can degrade scanning performance and lifecycle. In addition, the electronics are located in the top area of the DS7708 to prevent damage and protect uptime in the event of a spill.

Virtually invisible illumination

The LEDs are recessed behind the scan window, where they are barely visible and won’t disturb customers or cashiers.

Power through a single USB port

No additional power supply is required when connecting via USB, reducing accessory, installation and management costs.

Adobe Reader is required to open and view PDF files. This can be downloaded free from adobe.com.

Available Documents

DS7708_SSEASYMARK – Standard Wax

EASYMARK is the standard Weber wax ribbon which delivers consistent print

quality on any kind of paper label materials. It prints high density legible

barcodes and traceability data for short life labeling needs.

Geset 112 Bottom Labelling System

The Geset 112 labelling system is used to label square products on the bottom side automatically. Depending on the type and dimension of the product, different label sizes are used. The products are fed manually or by a conveying system provided by the customer at an infeed passage on the labelling system. Care should be taken on accurate alignment of the products. It is essential that the products are forwarded separately to the applicator with a gap between each other.

When the light barrier is reached, an application trigger is tripped. The label applicator applies then in Wipe On procedure a label onto the product. The label on bottom side is pushed on the product by the self-weight of the product. After labelling the products move on and can be removed from conveyor by the customer.

View ProductULTRAPRINT – High durability resin

ULTRAPLATE is the standard resin ribbon from Weber. It is dedicated to

applications requiring a perfect printing quality and excellent mechanical

resistances. Its high versatility (it also prints on coated papers) and its

performances (sharpness, printing speed) have resulted in making

ULTRAPLATE a market reference.

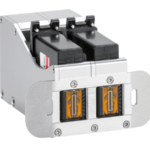

Markoprint NonStop Printing

To enable continuous marking in ongoing production, our Markoprint NonStopPrinting printhead holds two alternately printing cartridges. Because the other ink cartridge is printing on the same position, each ink cartridge can be changed, cleaned, or serviced without pausing the machine.

An intelligent automatism prevents both cartridges from going empty at the same time. The first cartridge will always print two consecutive print jobs, taking turns with the second cartridge, which will only print one. This sophisticated automatism avoids both cartridges from running out at the same time. This will keep the ink from drying out in both cartridges. When the cartridge with the larger print volumes is empty, a warning will show, and the other cartridge will continue printing until it is replaced. The new cartridge will print the lower quantities to allow for you to replace the “older” cartridge. A sophisticated workflow that will boost your efficiency and productivity.

View Product