For years’ craft brewers chose glass bottles to package their beer. The glass container was seen as the only viable option for small operations. Brewers were able to buy glass bottles in bulk and then label them on-site with minimal investment in packaging equipment. For many consumers, they believed the quality of the beer would be better if the beverage was stored in glass. There was also the belief that canned beer would leave a metallic taste from the aluminium.

But a lot has changed in packaging technology.

In the last few years, the aluminium industry has found ways to make the cans more light-weight and they’re squashing the flavour myth. Additionally, cans are recycled more and, because of their opaque material, they preserve the flavour longer than glass. Due to its recyclability and preservation, some consumers are reaching for cans more than bottles these days. But the one drawback that still makes it difficult for craft brewers to switch to cans is the high minimums of pre-printed cans and the cost of canning machinery.

A solution to this can vs. bottle debate is to use blank cans with pressure-sensitive labels. Brewers can buy the blank cans in bulk without storing thousands of pre-printed cans may become obsolete. To manage your inventory, you can order custom labels based on the quantity you want to apply without holding onto extra materials. If you’re still growing, you might not have the storage space to store all those pre-printed cans.

Some breweries are moving to shrink sleeve label material for their cans. This is a great solution but you’ll still need to have the volume that allows for the investment of the application equipment. It’s not something that can be applied by hand.

If you’re just starting out, or want to label both cans and bottles, pressure-sensitive labels will keep your look consistent and keep the packaging cost down. The same equipment used to label your 12oz or 22oz beer bottles will also work for your cans. Plus, if you decide to want to offer crawlers at your taproom, you can apply the pressure-sensitive labels straight to the can without large labelling equipment.

Pressure-Sensitive Can Labelling Options

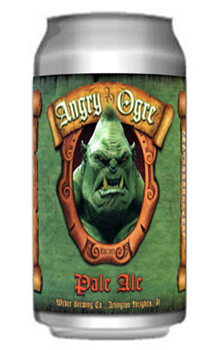

Your best bet for labels for craft beer cans is a film or BOPP label material. The adhesive will be strong enough to adhere to the can and the face stock will be durable enough to maintain your design even if it’s stored in a wet environment like a refrigerator or cooler full of ice.

Plus, if you use a clear film label material, you’ll be able to incorporate the shiny metallic look of the aluminium can into your design. Or you can also choose a metallized material which will add even more pop to the design.

If you have any questions about craft beer labels or labelling cans, contact our Beer Labelling Expert and get samples and a quote.